MagSphere

NdFeB & SmCo Magnets

NdFeB (Neodymium-Iron-Boron) magnets are the strongest permanent magnets available today. They are manufactured in two major forms:

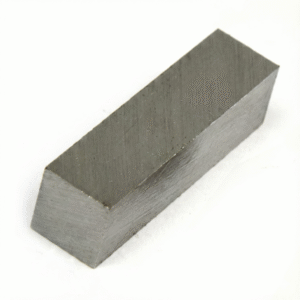

1. Sintered NdFeB Magnets

- Produced through powder metallurgy (pressing + sintering)

- Extremely high magnetic strength (BHmax)

- Used in EV motors, wind turbines, robotics, medical devices, and industrial motors

- Require anti-corrosion coatings such as Ni-Cu-Ni or epoxy

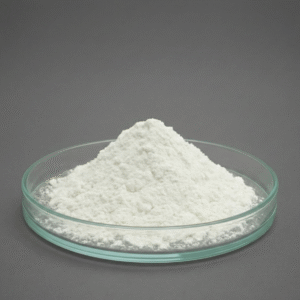

2. Bonded NdFeB Magnets

- Made by combining NdFeB powder with polymers/resins

- Supports complex shapes and tight dimensional tolerances

- Lower strength compared to sintered magnets

- Used in sensors, micro‑motors, precision assemblies, and electronics

Sintered magnets are ideal for high‑power applications, while bonded magnets are preferred for compact, lightweight designs and shapes not possible with sintered materials.

| Feature | Sintered NdFeB Magnets | Bonded NdFeB Magnets |

|---|---|---|

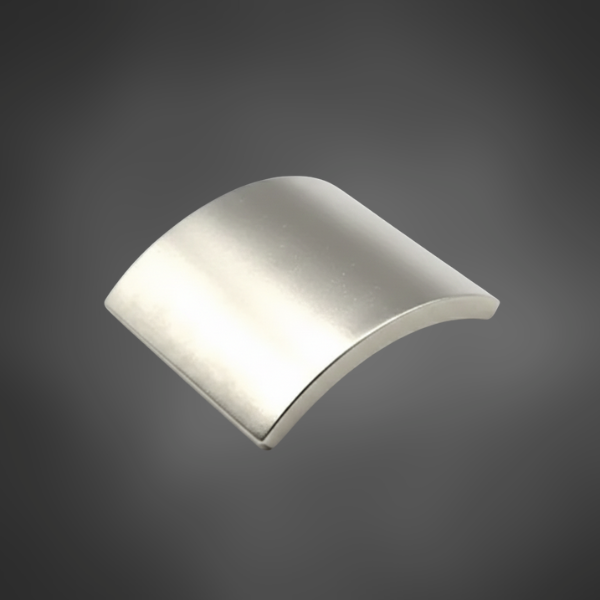

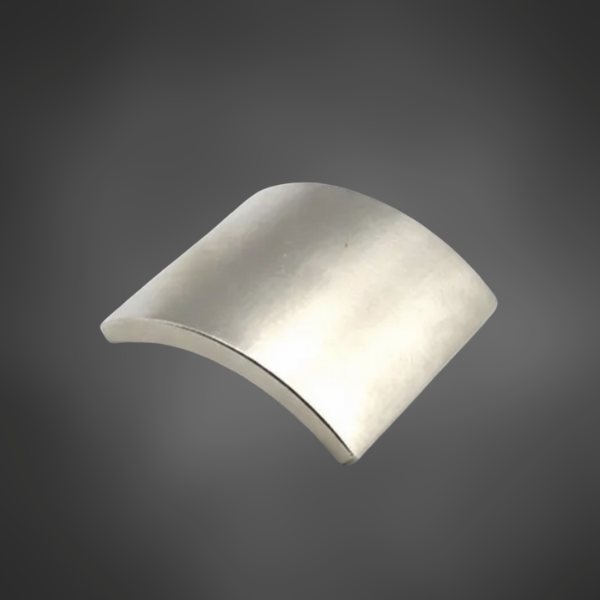

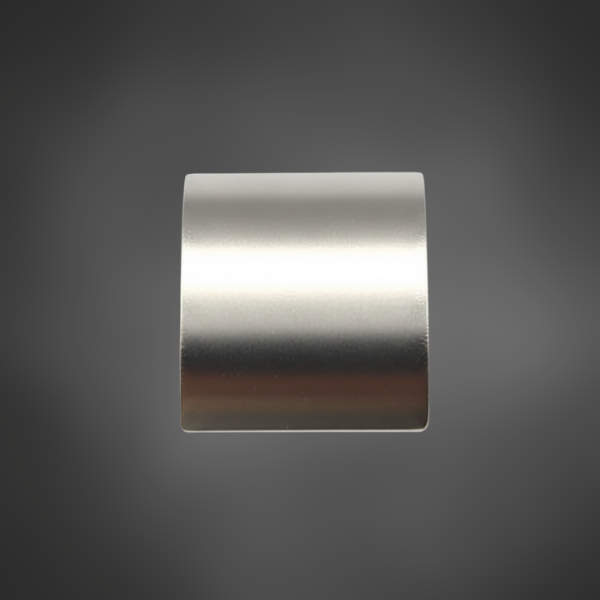

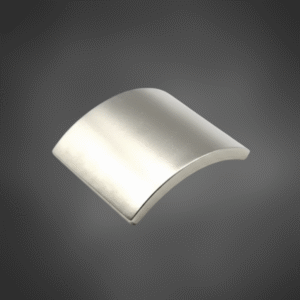

| Appearance | Shiny and metallic due to a typical nickel-copper-nickel coating to prevent rust. | Duller, often darker surface, resembling a hard plastic or composite material due to the polymer binder. |

| Surface Finish | Very smooth and uniform, often with sharp edges from the precision cutting process. | May have a slightly textured or matte finish; edges can be smoother or molded into specific features. |

| Shapes | Usually simple, geometric shapes (discs, blocks, rings) which are cut from larger blocks. | Can be formed into complex, intricate shapes and components with features that are difficult to achieve with the brittle sintered material (e.g., specific gear shapes, multi-pole rotors). |